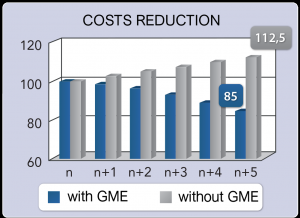

FactoryGME brings together in one single platform production and maintenance management functionalities in order to create a complete MES software that combines production and maintenance management. The software is based on the G.M.E method, which significantly improves the performance of a company.

The primary feature of the MES FactoryGME software is that it describes the entire enterprise through photographs and plans. Each workstation is represented virtually. This graphical technical tree is the center of an interface that lists all the events : anomalies to be reported, works to be performed, spare parts to be searched, tasks to be notified, documents to be validated, etc.

Designed by and for field users, it combines user-friendliness and performance. Prized as managers and operators, it stands out as a powerful lever for improvement.

EN

EN Fr

Fr