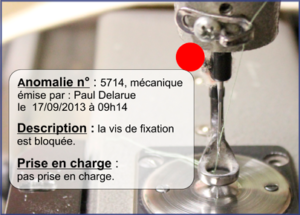

The CMMS of factory GME software uses color cards to effectively manage maintenance work and technical defects.

In CMMS, the main tool for recording work is WO or Work Order, sometimes preceded by a notice. Factory Systems’ CMMS software uses color dots to better symbolize problems or actions. These various cards contain all the necessary information for a fast and efficient treatment of maintenance work or technical anomalies. They are either issued by the production (or the “supply chain”) or by the maintenance for the management of its own work.

EN

EN Fr

Fr