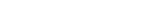

Le technicien a besoin d’un roulement à une rangée de billes pour remonter un tambour de convoyeur. Il a démonté l’ancien pour prendre les mesures car le numéro est effacé : diamètre extérieur, diamètre de l’axe, largeur et protections. Il interroge le logiciel GMAO en suivant l’ordre suivant :

Login et mot de passe->Bouton « pièces de rechange »->Famille « roulements à billes »

The technician needs a single-row ball bearing to reassemble a conveyor drum. He dismounted the old one to take the measurements because the number is erased : outside diameter, diameter of the axis, width and protections. He questions the CMMS software in the following order:

Login and password > Box “spare parts” > Family “ball bearings”

The screen shows all the ball bearings of the stock and at the same time a filter of technical choice allowing the following progression:

Rows: 1 > Ext. Diam > Int. Diam. > Width > Protections

The desired bearing is displayed (if it is pre-encoded) with available stock and in-store location. The technician takes it away or reserves it for later or requests an order if the stock is at zero. Estimated time: 74 seconds.

If the bearing number was known, the routing would have been much shorter :

Login & password > Spare parts button > Search «6204 2RS bearing»

Available stock and location appear immediately. Estimated time: 31 seconds.

EN

EN Fr

Fr