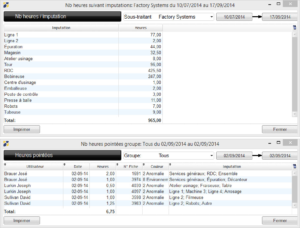

Maintenance work planning is managed in real time by the CMMS of factory GME software.

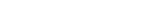

The maintenance shop management plan gives managers a clear and instant view of the workload of their department.

It displays in a single screen weekly jobs scheduled and allocated to different technicians or subcontractors.

It is designed to use data generated by production or maintenance, avoiding copying and automating as many tasks as possible.

EN

EN Fr

Fr