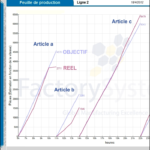

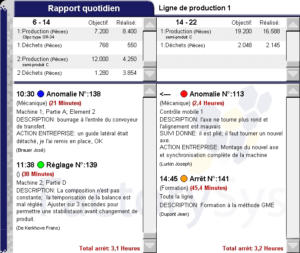

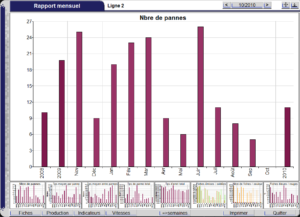

The CAPM of factory GME software manages your real time production monitoring by communicating performance instantanly (trg, waste, quantities produced …) and by performing global or detailed custom reports.

The production module contains a series of submodules, each with a specific role :

EN

EN Fr

Fr