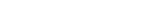

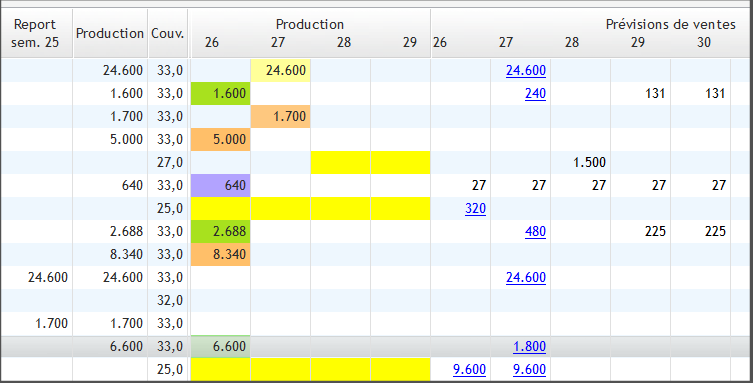

The CAPM of factory GME software offers an integrated or autonomous module for the lines or equipments planning starting from sales forecasts, orders and stocks.

The manufacturing schedule is a complete software that can operate either autonomously or as a module integrated into FactoryGME.

It is developed for planning production lines or equipments from sales forecasts, orders and stocks.

EN

EN Fr

Fr