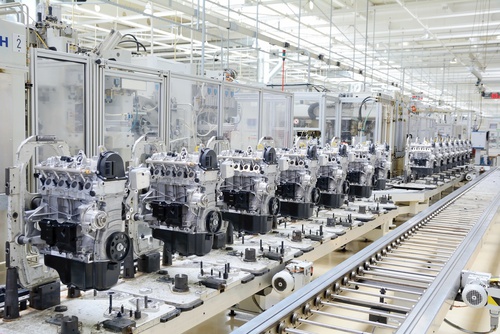

The supply of a product to the customer without incurring any loss during the overall design, production and delivery chain is a perfect match for the requirements of “lowest cost, zero defect, immediately.”

To achieve these objectives, the GME methodology endeavours to reduce every possible losses that will be evaluated and treated in relation to their seriousness and urgency, relevant measuring indicators (KPI’s and OEE) monitor the progress made. These include the OEE or overall equipment efficiency a measure of how comprehensive the process efficiency.